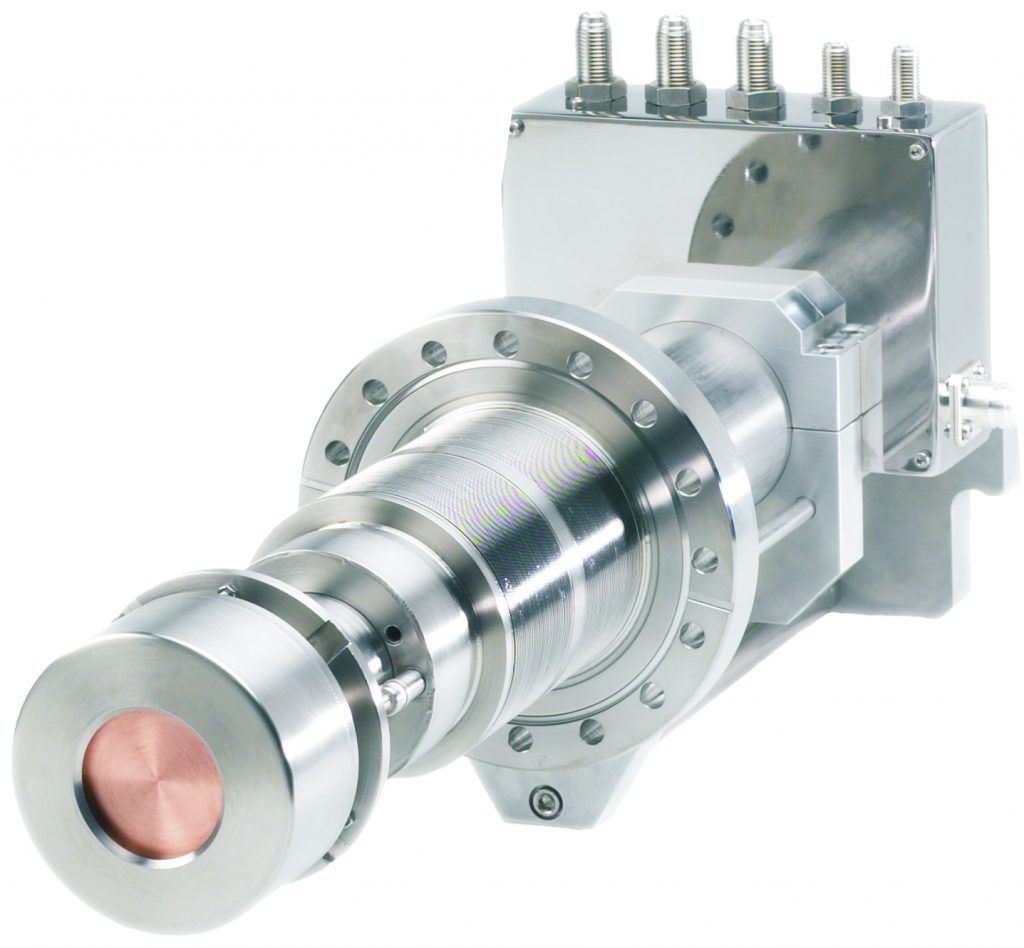

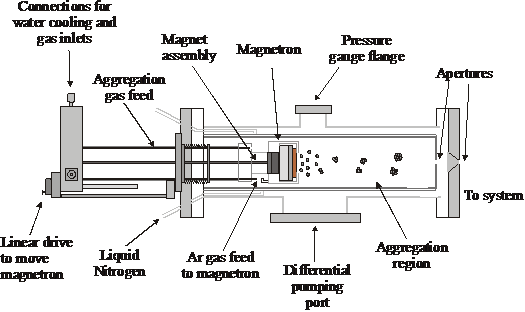

| Oxford Applied Research manufactures a nanocluster source based on the gas condensation technique and can be used to deposit a wide range of clustered materials for research and industrial applications. The NC200U-B is a combined RF/ DC magnetron which is used to sputter material into a liquid nitrogen-cooled, high pressure aggregation/ drift region. The clusters form in this region and are then channelled through apertures into the user’s system. |

| The source is fully UHV-compatible and bakeable. It is efficiently water cooled, has the provision for 3 aggregation gases, and also includes a differential pumping T-piece. Variable cluster size The cluster size can be adjusted by varying three main source parameters: the length in which the clusters aggregate, the power to the magnetron and the flow of the aggregation gas. In terms of the cluster size range the magnetron-based source is the most flexible. For a large number of materials the source is capable of producing clusters consisting of a few tens of atoms up to particles with diameters greater than 10nm. |

| High deposition rates The NC200U-B source is capable of depositing at rates between <0.001nm/s and >0.5nm/s (measured at a distance of 100mm for Cu clusters). The deposition rate depends on a number of parameters which includes the material and the size of clusters required. High ionised cluster content A large percentage of the clusters generated by the source are ionised (typically 40% for Cu clusters). An ionised beam can be accelerated towards a substrate to form highly adherent and uniform coatings. This technique, so called energetic cluster impact (ECI), can be used to form dense films on otherwise-difficult materials, such as Teflon. The ionised clusters can also be electrostatically manipulated in the deposition system. Mass can be measured and selected by the QMF200 quadrupole mass filter. Materials The NC200U-B uses standard 2″ sputter targets and can produce clusters of a number of elements including semiconductors, magnetic materials and most metals. Compound clusters, such as TiO2 can also be formed by adding oxygen to the aggregation region during operation. Options We also offer a quadrupole mass filter, a neutral cluster filter, ion deflection plates and complete nanocluster deposition systems. |

AFM image showing 10nm thick film of ~5nm diameter Co clusters deposited using the NC200U. The deposition time for this film was less than a minute.

TEM image showing Si clusters deposited using the NC200U.